Turning industrial wastewater into a source of critical raw materials with unmatched efficiency.

Discover our breakthrough process at the core of Circular Materials.

At Circular Materials, we harness the power of Supercritical Water—above 374°C and 221 bar—to recover valuable metals from industrial wastewater. Each incoming waste stream reach of metals is tracked, analyzed to identify the best treatment conditions to be processed in our continuous-flow reactor. Dissolved metals rapidly precipitate into fine, pure powders, enabling efficient separation from water. The result: a 99%+ recovery rate, clean water ready for reuse, and high-value secondary raw materials re-entering the industrial cycle.

Our SWaP (Supercritical Water Precipitation) is the only patented technology able to recover strategic metals from industrial waste streams and simultaneously treat wastewater and recovers metals, eliminating toxic sludge production, through a sustainable and highly efficient process.

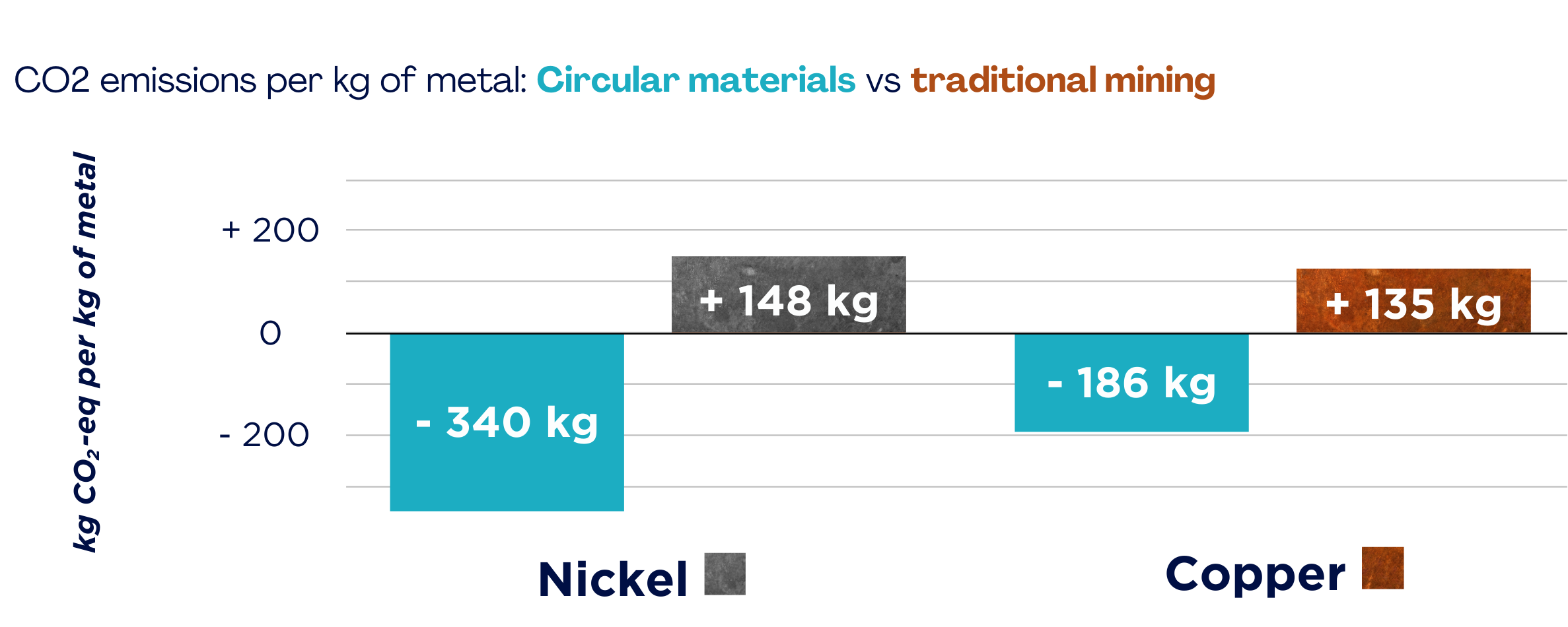

The most sustainable way to use your waste and raise your ESG profile.

Any metal, any concentration, any composition.

The best recovery of metals from your streams.

You call, we collect.

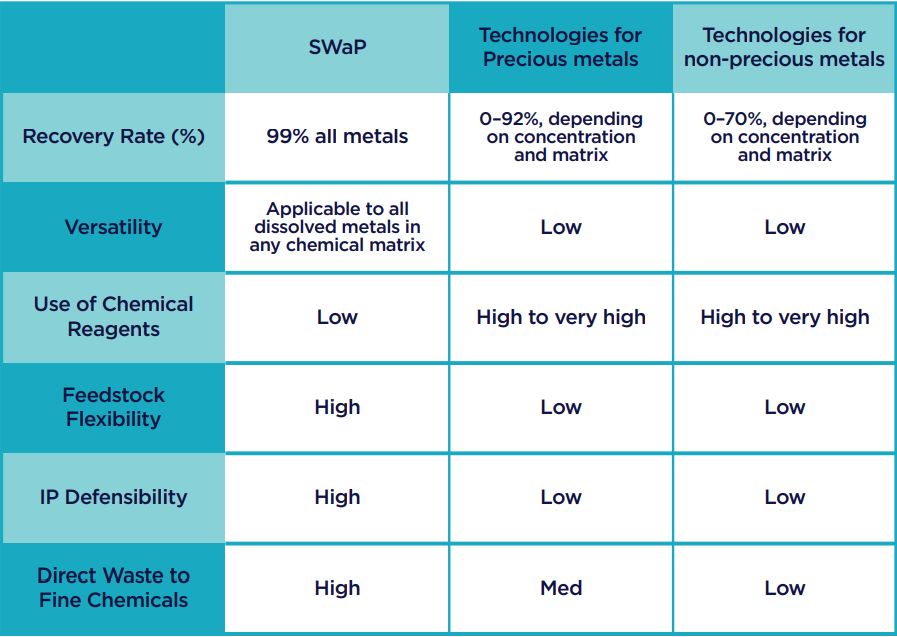

The SWaP technology, unlike traditional methods, unlocks the full value of metal-rich wastewater. It is uniquely versatile, capable of recovering both precious and non-precious metals through a single, scalable, and sustainable process.

SWaP opens an untapped global market of industrial waste streams not addressed by current state-of-the-art technologies.